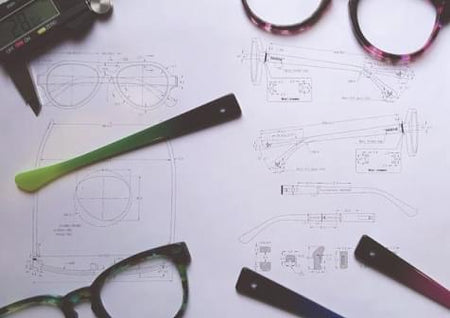

Design

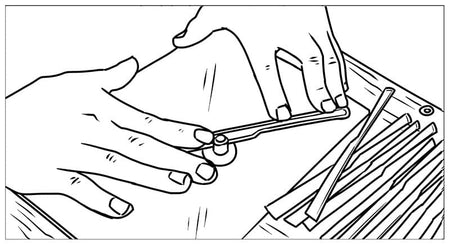

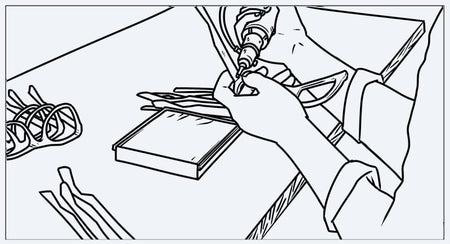

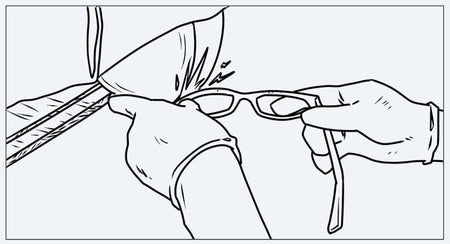

As with all good products, we spent a lot of time with our designer reviewing acetate chips and coming up with unique color combinations. Once done, we went through multiple rounds of prototypes and tried them on kids to make sure we got the right sizing and fit! With each round, we fine-tuned the technical design files until the blueprint for our product was optimized for all those cute little faces we had in mind.